3D Printing 101: The Ultimate Guide to 3D Printers

Everything You Need to Know About 3D Printers

Read this entire guide and you will know everything you need to know to get started with 3D Printing

3D printing technology is one of the most exciting and rapidly advancing fields of technology today. From hobbyists creating intricate prototypes to product designers revolutionizing entire industries, 3D printing has the power to change the way we live and work. If you’re reading this because you want to start 3D printing at home, you’re in the right place! At the end of this guide you will know everything you need to get started with your own 3D Printer project (and more!).

In this comprehensive guide, we will explore 3D printer technology, compare the advantages and disadvantages of each type, and take a look at some of the most popular 3D printers in each category. Additionally, we will delve into the different materials and processes used in 3D printing, as well as the current and potential applications of this technology in industries such as healthcare, manufacturing, and architecture.

We will also explore the future possibilities of 3D printing, including bioprinting and nanoprinting, and discuss the ethical and regulatory considerations surrounding this technology. With so much potential to revolutionize the way we live, this guide is a must-read for anyone interested in the world of 3D printing.

But first let’s talk about 3D Printing at home. 3D printing at home has become increasingly popular in recent years, thanks to the availability of affordable, user-friendly 3D printers.

One of the main advantages of 3D printing at home is the ability to create custom, one-of-a-kind items that may not be available commercially. From jewelry to board game pieces to replacement parts for household appliances, the possibilities are endless. Another advantage of 3D printing at home is the ability to quickly and easily create prototypes for new designs. This can be especially useful for inventors, artists, and DIY enthusiasts. With a 3D printer, hobbyists can test and iterate on new ideas without the need for expensive prototyping services.

In addition to creating unique items and prototypes, teachers can use their 3D printers to create educational materials. For example, many educators use 3D printing to create models and visual aids for science and math classes. 3D printing can also be used to create prosthetic limbs, surgical implants and dental restorations, and even organ and tissue replacements.

Tabletop game fans can also use 3D printing to create molds for casting, which can be used to make multiple copies of an object. This is particularly useful for creating figurines, custom game pieces, and other small items, for use in popular games such as Dungeons and Dragons.

Definition and History of 3D Printing

3D printing, also known as additive manufacturing, is a process of creating a three-dimensional object by laying down successive layers of material. The technology has come a long way since its invention in the 1980s, and it is now used in a wide range of industries, from manufacturing and healthcare to architecture and art.

Chuck Hull, the father of 3D Printing

The history of 3D printing can be traced back to the 1980s, when Chuck Hull, an American engineer, invented the first 3D printer (he’s been inducted into the National Inventors Hall of Fame!). Hull's printer used a process called stereolithography, which involved curing layers of liquid polymer with ultraviolet light. This was the first time that a machine could create a solid object from a digital design, and it marked the beginning of the 3D printing revolution.

In the years that followed, several other 3D printing technologies were developed, such as Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). These technologies made 3D printing more accessible and more affordable, and they opened up new possibilities for the use of 3D printing in different industries, including 3D printing at home for DIY enthusiasts and other makers.

Today, 3D printing is used in a wide range of applications, from prototyping and manufacturing to healthcare and architecture. In the manufacturing industry, for example, 3D printing is used to create prototypes and molds for casting, while in the healthcare industry, it is used to create prosthetic limbs, dental implants, and even human organs.

The future of 3D printing looks bright, with new developments in the field such as bioprinting, which has the potential to revolutionize the way we create human organs, and nanoprinting, which has the potential to create smaller and more precise parts than ever before. With these and other advancements, 3D printing is sure to play an increasingly important role in many industries in the years to come.

Overview of Current State of the 3D Printing Industry

The 3D printing industry has grown significantly in recent years, with the global market size projected to reach $42 billion by 2027, according to a report by Grand View Research. This growth can be attributed to advances in technology, a decrease in costs, and an increase in the range of materials and applications that 3D printing can be used for.

One of the major drivers of the 3D printing industry is the advancements in technology. According to a report by Mordor Intelligence, the market for metal 3D printing is expected to grow at a compound annual growth rate (CAGR) of 24.2% during the forecast period of 2020 to 2025. This is due to the development of new techniques such as direct energy deposition, which allows for larger and more complex parts to be printed, as well as the increasing adoption of metal 3D printing in the aerospace and medical industries.

Another driver of the 3D printing industry is the decrease in costs. The cost of 3D printers has decreased significantly in recent years, making them more accessible to small and medium-sized enterprises, which has led to an increase in the number of companies that are using 3D printing for prototyping and small-scale production.

The 3D printing industry is also seeing an increase in the range of materials that can be used. This is due to the increasing use of plastics in industries such as healthcare, aerospace, and automotive. Additionally, new materials such as ceramics, glass and even food are becoming available for 3D printing, expanding the possibilities of the technology.

The 3D printing industry is growing rapidly, driven by advancements in technology, decreasing costs, and an increase in the range of materials and applications. The market size is projected to reach $42 billion by 2027, with metal 3D printing and 3D printing plastics as some of the fastest-growing segments. The increasing accessibility and versatility of 3D printing are making it an increasingly important tool for various industries.

Now that we’ve briefly discussed how 3D printing technology is rapidly advancing and has the potential to revolutionize many industries, let’s explore the different types of 3D printers, including the materials and processes used, and the various applications and future possibilities of 3D printing.

Types of 3D Printers

Explanation of the different types of 3D printers available: FDM, SLA, SLS, DLP, and others

3D printing technology has come a long way since its invention in the 1980s, and there are now several different types of 3D printers available on the market. Each type of printer uses a different method to create a three-dimensional object, and each has its own advantages and disadvantages..

Let’s take a look at some of the most popular types of 3D printers: Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Digital Light Processing (DLP), and others.

However, remember that the specific needs of a project will determine which type of printer is the best fit so it's important to understand the technology and its capabilities before deciding on the right 3D printer for you.

Fused Deposition Modeling

Fused Deposition Modeling (FDM) is one of the most popular types of 3D printing. It works by heating and extruding plastic filament through a nozzle, which is then deposited layer by layer to create an object. The process is relatively simple and low cost, making it a popular choice for home and small-business use.

FDM 3D printers can print with a wide variety of materials, including Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Thermoplastic Polyurethane (TPU), Polyethylene terephthalate glycol (PETG), Nylon and more. Additionally, FDM printers are widely available, with many brands and models to choose from.

Fused Deposition Modeling Breakdown

Advantages

Widely available and affordable

Can use a variety of materials

Good for prototyping and small-scale production

User-friendly

Disadvantages

Lower resolution and surface finish compared to other types of 3D printers

Prone to warping and stringing

Materials have limited strength and durability

Not suitable for highly detailed or precise parts

Best Use Case

Prototype models

Small-scale production

Education and hobbyist projects

Stereolithography

Stereolithography (SLA) is another popular type of 3D printing. It works by curing liquid resin with a UV laser, which solidifies the resin layer by layer to create an object. SLA printers are known for their high resolution and precision, making them ideal for creating detailed models and prototypes. However, the process is more expensive and the materials used can be more costly than FDM.

Stereolithography 3D Printers

Advantages

High resolution and surface finish

Can use a variety of materials

Suitable for highly detailed and precise parts

Good for small-scale production

Disadvantages

More expensive than FDM printers

Materials have limited strength and durability

Not suitable for large-scale production

Requires post-processing to remove support structures

Best Use Case

Jewelry and dental models

Medical and scientific models

Artistic projects

Selective Laser Sintering

Selective Laser Sintering (SLS) is a type of 3D printing that uses a laser to fuse together powdered materials to create an object. SLS printers are best used for creating complex geometries and they can print with a wide range of materials, including metals, ceramics, and even glass. However, SLS printers are typically more expensive than FDM and SLA printers, and the process can be more time-consuming.

Selective Laser Sintering 3D Printers

Advantages

High resolution and surface finish

Can use a variety of materials

Suitable for large-scale production

Good for creating functional parts

Disadvantages

More expensive than FDM and SLA printers

Materials have limited strength and durability

Not suitable for highly detailed or precise parts

Requires post-processing to remove support structures

Best Use Case

Automotive and aerospace parts

Industrial and manufacturing parts

Medical implants

Digital Light Processing

Digital Light Processing (DLP) is a type of 3D printing that uses a digital light projector to cure a liquid resin. DLP printers are similar to SLA printers in terms of resolution and precision, but the process is typically faster and more cost-effective.

Digital Light Processing 3D Printers

Advantages

High resolution and surface finish

Can use a variety of materials

Suitable for small-scale production

Good for creating highly detailed and precise parts

Disadvantages

More expensive than FDM and SLA printers

Materials have limited strength and durability

Not suitable for large-scale production

Requires post-processing to remove support structures

Best Use Case

Jewelry and dental models

Medical and scientific models

Artistic projects

Other Types of 3D Printers

Other types of 3D printers that are gaining popularity in different industries include Multi Jet Fusion (MJF), Binder Jetting, and Material Jetting. Each of these technologies offers its own set of advantages and disadvantages and it's important to understand the specific needs of a project before deciding on the right printer.

Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Digital Light Processing (DLP), and other types of 3D printers all have their own unique capabilities and limitations. It's important to do your research and understand the technology and its capabilities before making a decision.

By understanding the different types of 3D printers available and their pros and cons, you can make an informed decision and ensure that you choose the right printer for your project.

Chances are that you’re going to want a FDM 3D printer if you’re looking to jump into the world of 3D printing at home. The other types of 3D printers are much more suited to industrial and business purposes, although having a DLP printer at home would be pretty badass!

Examples of popular 3D printers in each category

As mentioned above, Fused Deposition Modeling (FDM) is one of the most popular types of 3D printing, especially when it comes to 3D printing at home. Some popular examples of FDM printers include the Ultimaker 3, the Prusa i3 MK3S, and the LulzBot Mini. The Ultimaker 3 is known for its precision and ease of use, while the Prusa i3 MK3S is a reliable and affordable option. The LulzBot Mini is a popular choice for those looking for a compact and portable printer. Check out this post which discusses specific FDM printer models in more detail.

Stereolithography (SLA) is another popular type of 3D printing. Some popular examples of SLA printers include the Formlabs Form 2, the Anycubic Photon, and the Peopoly Phenom. The Formlabs Form 2 is a high-end option known for its precision and high-resolution prints. The Anycubic Photon is a more affordable option that offers good print quality. The Peopoly Phenom is a large format SLA printer that can print large and detailed models. Check out this post which discusses specific SLA printer models in more detail.

The EOS P110, a popular model of SLS 3D Printers

Selective Laser Sintering (SLS) is a type of 3D printing that uses a laser to fuse together powdered materials to create an object. Popular examples of SLS printers include the EOS P110, the ProX SLS 500, and the Sinterit Lisa. The EOS P110 is a high-end option known for its precision and ability to print with a wide range of materials. The ProX SLS 500 is a more affordable option that offers a large build volume. The Sinterit Lisa is a compact and affordable SLS printer. Check out this post which discusses specific SLS printer models in more detail.

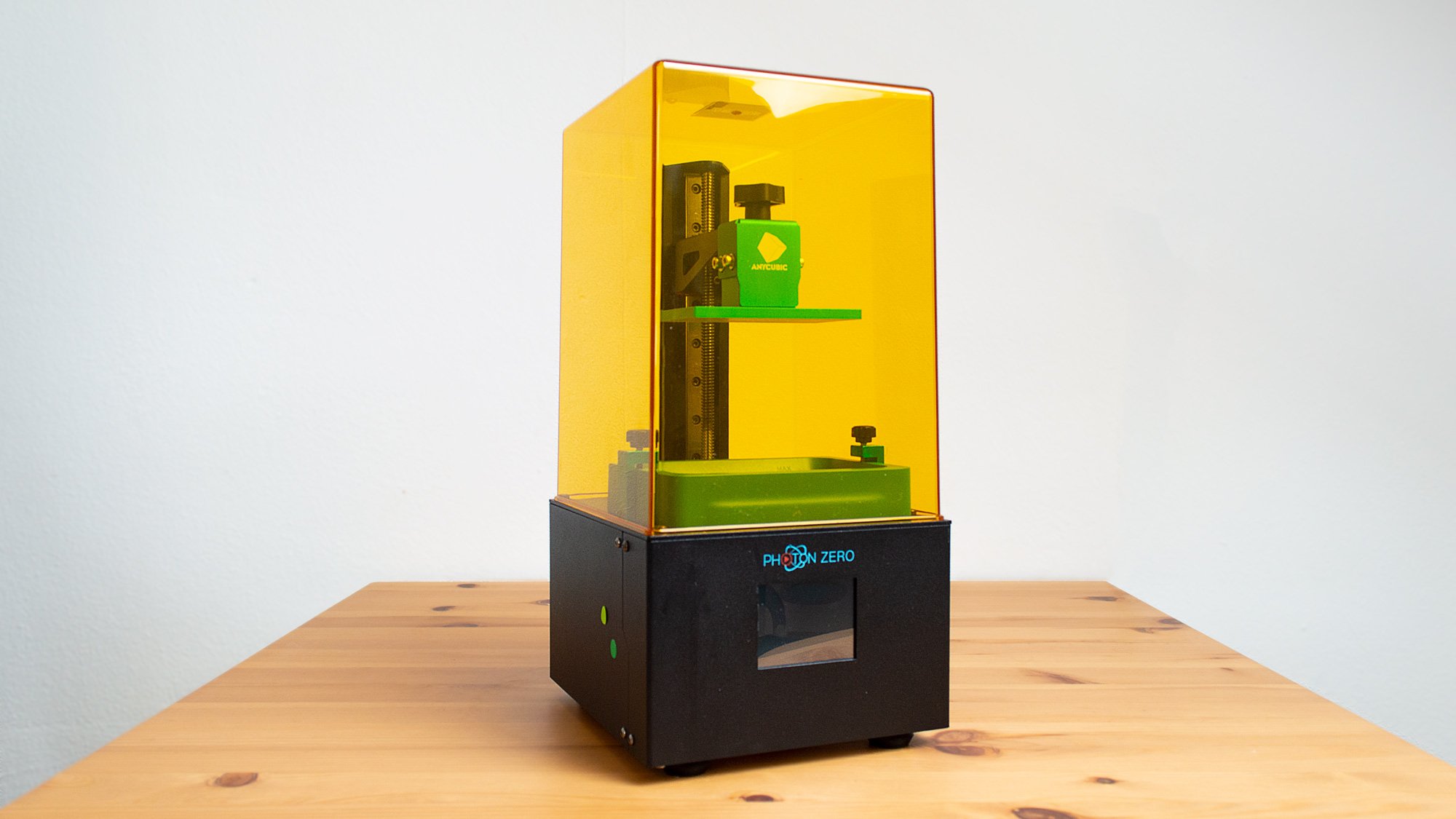

Image of the Photon Zero, a model that uses DLP tech

Digital Light Processing (DLP) is a type of 3D printing that uses a digital light projector to cure a liquid resin. Some popular examples of DLP printers include the Photon Zero, the Anycubic Photon S, and the Mars Pro. The Photon Zero is a compact and affordable option that offers high resolution and precision. The Anycubic Photon S is a more advanced option that offers an improved build volume and faster printing speeds. The Mars Pro is a large format DLP printer that offers high precision and a large build volume. Check out this post which discusses specific DLP printer models in more detail.

Other types of 3D printers include Multi Jet Fusion (MJF), Binder Jetting, and Material Jetting. Popular examples of MJF printers include the HP Jet Fusion 5200 and the EOS P 800. Binder Jetting printers such as the ExOne Innovent+ and the ProX DMP 320 are becoming more popular in industries such as aerospace, automotive and healthcare. Material jetting printers, like Stratasys J735 and HP Jet Fusion 4200 are also gaining popularity as they offer high precision and a wide range of material compatibility. These are newer 3D printing technology and thus are not as common and are more expensive than the other.

3D Printer Materials and Processes

3D printing technology has opened up new possibilities for creating objects and prototypes with different materials. We just discussed the different types of 3D printers available, but each type of printer uses its own specialized material in a unique way. Now, let’s dive in deeper and take a closer look at the different materials that can be used in 3D printing, specifically: plastics, metals, ceramics, and others.

Plastics are one of the most popular materials used in 3D printing. They are lightweight, durable and easy to use. There are a wide variety of plastic filaments available for use in FDM printers such as Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Thermoplastic Polyurethane (TPU), Polyethylene terephthalate glycol (PETG), and Nylon. These materials have different properties, such as flexibility, strength, and heat resistance, which makes them suitable for different applications. For instance, ABS is known for its strength and durability while TPU is known for its flexibility. See my post on the different materials used in FDM printers for a more comprehensive discussion on the variety of filament types for FDM printing.

Metals are also widely used in 3D printing. Metal 3D printing is mainly used for the production of small-scale parts and prototypes. The most common metal materials used in 3D printing are titanium, stainless steel, and aluminum. Metal 3D printing is mainly used in aerospace, automotive and medical industries, where the need for high strength and precision is required. Metal 3D printing has a high cost and requires post-processing work.

Ceramics are another popular material used in 3D printing. Ceramic 3D printing is mainly used for creating intricate and complex geometries. The most common ceramic materials used in 3D printing are alumina and zirconia. Ceramic 3D printing is mainly used in the dental, aerospace, and medical industries, where the need for high precision and biocompatibility is required. Ceramic 3D printing is also expensive, needs post-processing work, and has limited material options available.

Other materials that can be used in 3D printing include glass, concrete, and food. Glass 3D printing is mainly used for creating intricate geometries and is mainly used in the optical and jewelry industries, Concrete 3D printing is mainly used in the construction industry, and food 3D printing is mainly used in the culinary industry.

The different 3D printing processes explained: extrusion, curing, sintering, and more

There are several different processes used to create three-dimensional objects. Let’s continue our dive into the world of 3D printing and look at the different 3D printing processes: extrusion, curing, sintering, and others.

Extrusion

Extrusion is one of the most popular 3D printing processes and this is the method that you’re likely most familiar with. It is used in Fused Deposition Modeling (FDM) printers, which are widely available and affordable, and used by most 3D printers at home. The process works by heating and extruding a filament of plastic, which is then deposited layer by layer to create an object. One of the main advantages of FDM is its low cost, as the process uses common and inexpensive filaments such as ABS and PLA. FDM is also known for its wide material compatibility and ease of use. However, one of the main disadvantages of FDM is that the printed objects may have a lower resolution and a rougher surface finish when compared to other processes.

Curing

Curing is another popular 3D printing process. It is used in Stereolithography (SLA) and Digital Light Processing (DLP) printers. The process works by curing a liquid resin with a UV light, which solidifies the resin layer by layer to create an object. SLA and DLP are known for their high resolution and precision, but they are more expensive than FDM 3D printers. One of the main disadvantages is that the process can be more time-consuming and require more post-processing work, as the objects need to be cleaned, cured, and sanded, which naturally results in a more expensive process.

Sintering

Lasers are cool! Sintering is a type of 3D printing process that uses a laser to fuse together powdered materials to create an object, most commonly used in Selective Laser Sintering (SLS) printers. One of the main advantages is its ability to create complex geometries and print with a wide range of materials, including metals, ceramics, and even glass. However, the process can be more time-consuming and the parts may have a rougher surface finish.

Other innovative processes of 3D Printing

Other 3D printing processes include Multi Jet Fusion (MJF), Binder Jetting, and Material Jetting. These processes use different techniques and materials to build objects. MJF uses a combination of heat, pressure, and a fusing agent to fuse together a bed of powdered materials. MJF is known for its high precision and material compatibility but it is relatively new in the market.

Binder jetting uses a liquid binder to bind together a bed of powdered materials. Binder Jetting is known for its fast printing speed and good surface quality, but it needs post-processing work.

Material jetting uses a print head to deposit droplets of material layer by layer. Material Jetting is known for its high resolution and material compatibility, but it is relatively expensive.

As we’ve seen, there are many different 3D printing materials and processes available, such as extrusion, curing, sintering, and other processes. They all have their own advantages and disadvantages, and it's important to define the specific needs of a project before deciding on the right process.

Real World Applications of 3D Printing

3D printing technology is long past its infancy, and it is now being used in a wide range of industries. So far, we’ve discussed the various types of 3D printers and materials they use. Now let’s discuss the current applications of 3D printing in various industries: manufacturing, healthcare, architecture, and others in addition to DIY makers using 3D printers at home.

Manufacturing is one of the industries that has been most heavily impacted by 3D printing. 3D printing technology is being used in manufacturing to create prototypes, tools, and even end-use parts. According to a report by Mordor Intelligence, the manufacturing industry is expected to be one of the largest adopters of 3D printing technology. It is being used to produce parts for aerospace, automotive and medical industries where the need for high precision and complex geometries is required. 3D printing technology is also being used to produce spare parts for the maintenance of machines, which reduces the need for inventory and storage.

Healthcare is another industry that is making use of 3D printing technology. 3D printing is being used to create prosthetics, implants, and even organs. 3D printing technology is being used to produce customized prosthetics and implants that are tailored to the patient's needs. This leads to a better fit and improved functionality. 3D printing technology is also being used to create models of organs, which are used in surgical planning and training.

Architecture is another industry that is making use of 3D printing technology. 3D printing technology is being used to create scale models of buildings and structures, which are used in the design and planning stages. It is also being used to create full-scale models of buildings and structures, which are used for testing and validation.

3D printing technology is also being used to create clothing, accessories, and even food. 3D printing technology is also being used to create jewelry which is customized to the customer's needs. Imagine designing an engagement ring on your computer and then 3D printing it before your proposal, or eating a 3D printed sandwich!

As 3D printing technology continues to advance, it will likely continue to play an even bigger role in various industries, revolutionizing the way things are made and improving the efficiency and effectiveness of many processes.

Potential future applications of 3D printing in areas such as aerospace, automotive, and construction

3D printing technology has been around for decades and it has already begun to revolutionize a number of industries. Let’s discuss the potential future applications of 3D printing in areas such as aerospace, automotive, and construction.

Aerospace is an industry that is expected to see significant growth in the use of 3D printing technology. According to a report by MarketsandMarkets, the aerospace industry is expected to be one of the largest adopters of 3D printing technology in the future. 3D printing is already being used to create parts for aircraft and spacecraft, and in the future, it is expected to be used to create entire aircraft and spacecraft. 3D printing is also expected to be used to create lightweight and high-strength parts, which will improve the efficiency and performance of aircraft and spacecraft.

Automotive is another industry that is expected to see significant growth in the use of 3D printing technology. 3D printing is already being used to create parts for automobiles, and in the future, it is expected to be used to create entire automobiles. It is also expected to be used to create lightweight and high-strength parts, which will improve the efficiency and performance of automobiles.

Construction is another industry that experts predict will see significant expansion of the use of 3D printing technology. 3D printing is already being used to create parts for buildings and structures and it is expected to be used to create entire buildings and structures. It is also expected to be used to create lightweight and high-strength parts, which will improve the efficiency and performance of buildings and structures.

This incredible technology is expected to be used to create entire aircrafts, spacecrafts, automobiles and buildings, as well as to create high-strength, lightweight and customized parts. With its ability to improve efficiency, reduce waste and cost, 3D printing is poised to revolutionize these industries and change the way things are built and manufactured. As the technology continues to advance and become more widely adopted, it will open up new possibilities and opportunities for innovation and growth.

Examples of companies and products that are currently using 3D printing in their operations

Let’s take a look at specific examples of 3D printing utilization by industry and business.

One example of a company using 3D printing in their operations is GE Aviation. According to GE, they have been using 3D printing technology to create fuel nozzles for jet engines since 2016. The technology allows them to create the nozzles with a more complex design, which improves their performance. GE has also stated that they have been able to reduce the weight of the nozzles by 25% and the number of parts required to make them by 30%.

Another example is Nike, Inc. According to Nike, they have been using 3D printing technology to create prototypes of shoe designs since 2017. The technology allows them to create a physical model of the shoe, which they can then test and make adjustments to. This helps them to speed up the design process and get products to market more quickly.

A third example of a company using 3D printing in their operations is Siemens AG. According to Siemens, they have been using 3D printing technology to create spare parts for their wind turbines since 2018. The technology allows them to create spare parts on demand, which reduces the need for inventory and storage. This helps them to reduce their costs and improve their efficiency.

Procter & Gamble are also using 3D printing in their operations. According to P&G, they have been using 3D printing technology to create prototypes of their product packaging since 2019. The technology allows them to create a physical model of the packaging, which they can then test and make adjustments to. This helps them to speed up the design process and get products to market more quickly.

Lastly, Stratasys is another example of a company using 3D printing in their operations. According to Stratasys, they have been using 3D printing technology to create prototypes of their products since 1989. The technology allows them to create a physical model of the product, which they can then test and make adjustments to. This helps them to speed up the design process and get products to market more quickly.

Many other companies are currently using 3D printing technology in their operations to improve performance, speed up the design process, reduce costs and improve efficiency. As the technology continues to evolve, we can expect to see more companies adopt it and create new and innovative products.

Future Possibilities for 3D Printing

Bioprinting

3D printing technology has grown considerably over the last decade and is beginning to revolutionize a number of industries. However, there are still many potential future developments in 3D printing technology that could have even greater impact. Let’s look to the future and discuss a few of the most promising areas of development, such as bioprinting, nanoprinting, and others.

One of the most exciting areas of development in 3D printing technology is bioprinting. Bioprinting is the process of using 3D printing technology to create living tissue and organs. One of the most significant implications of bioprinting is its potential impact on the healthcare industry. The technology is already being used to create small structures such as blood vessels and heart tissue, and in the future, it is expected to be used to create entire organs, such as livers and kidneys. This could potentially alleviate the shortage of organ donors and reduce the need for organ transplants.

Nanoprinting

Another area of development in 3D printing technology is nanoprinting. Nanoprinting is the process of using 3D printing technology to create structures at the nanometer scale, and has huge potential to impact the electronics industry. The technology is already being used to create small structures such as transistors and solar cells, which could potentially lead to the creation of faster, more efficient, and more powerful electronic devices. In the future, it is expected to be used to create even smaller structures, such as DNA and proteins. Experts expect the global nanoprinting market is expected to continue its rapid growth.

Multi-Material Printing

A third area of development in 3D printing technology is multi-material printing. Multi-material printing is the process of using 3D printing technology to create structures using multiple materials at the same time. The technology is already being used to create structures using a combination of metals, plastics, and ceramics, and in the future, it is expected to be used to create structures using a wider range of materials, such as wood and glass. Multi-material printing has great potential to impact the manufacturing industry. It has the potential to revolutionize the way we create and produce things. For example, this could potentially lead to the creation of more complex and customized products.

While 3D printing technology is still in its developmental infancy (and is underutilized!), there are many potential future developments that could have even greater impact. Bioprinting, nanoprinting, and multi-material printing are some of the most promising areas of development that are expected to revolutionize how we create and produce things. Bioprinting has the potential to revolutionize healthcare, nanoprinting has the potential to revolutionize electronics, and multi-material printing has the potential to revolutionize manufacturing. As technology continues to evolve, we can expect to see more companies adopt it and create new and innovative products. These developments will likely open up new possibilities and opportunities for innovation and growth.

Ethical and regulatory considerations surrounding 3D printing

The new innovations in 3D printing technology are exciting, but not without controversy. One of the most significant ethical questions surrounding 3D printing at home is the potential for the creation of weapons, such as guns. It is controversial that anyone with the right type of 3D printer can print a weapon, raising concerns about the safety and security of society.

There are also concerns about the potential for 3D printed items to be used for illegal activities, such as counterfeiting or piracy.

Additionally, the tech of Bioprinting and Nanoprinting must contend with deep philosophical dilemmas. Just because we can, does it mean we should?

On top of that, there are legal and ethical questions to consider. Currently there is a lack of regulation surrounding bioprinting and its applications, which could lead to legal disputes over issues such as patent infringement and liability for injuries caused by bioprinted products.

We also must consider the legal concept of intellectual property. Bioprinting technology is still in its early stages of development, and there is a risk of companies and researchers patenting biological materials, which could limit access and stifle innovation.

What about Intellectual Property rights? There is a risk of companies and researchers patenting biological materials, which could also limit access and stifle innovation (and is quite likely already happening).

Additionally, there are concerns about the environmental impact of 3D printing, as the materials and process used may not be sustainable. 3D Printers at home pretty much exclusively use a plastic-derived filament, and with the current controversy around microplastics, it may not be the slam dunk solution we once thought it was.

Ethical considerations of bioprinting

Bioprinting technology has the potential to revolutionize the way we create and replace living tissue and organs. This could potentially alleviate the shortage of organ donors and reduce the need for organ transplants. Bioprinting can also be used in the field of cosmetic surgery and wound healing as it can be used to create cartilage, skin, and bone tissue.

But bioprinting is not without controversy. Bioprinting involves handling living cells, which can pose risks of contamination and infection. There are also concerns about the long-term safety and efficacy of bioprinted tissues and organs. Many long-term studies need to be performed on 3D printed transplants before I’ll consider it for myself!

There are also ethical issues surrounding human tissue: Bioprinting technology could potentially be used to create human organ tissue or even whole organs. This raises ethical issues around the use of human tissue for medical research and organ replacement.

Bioprinting is not limited to human tissue, and scientists are already working on bioprinting animals, which raises additional ethical questions about the treatment of animals and the welfare of the bioprinted animals themselves. Could we theoretically bioprint a dog customized to have the exact traits we desire, and assemble it piece by piece?

Ethical considerations of nanoprinting

Nanoprinting technology has the potential to revolutionize the way we create electronic devices and circuits. As discussed earlier, the technology is already being used to create small structures such as transistors and solar cells, and in the future, it is expected to be used to create even smaller structures, such as DNA and proteins, which could potentially lead to the creation of faster, more efficient, and more powerful electronic devices.

However cool this may sound, it is not without potential controversy. There are a number of safety, environmental and societal concerns related to nanoprinting. For example, Nanoparticles can be highly reactive and potentially toxic, and there are concerns about the long-term safety and health risks associated with exposure to these materials. Imagine getting a 3D printed heart transplant that results in cancer (or an increase of microplastics in your blood).

Environmentally speaking, the release of nanoparticles into the environment could have unintended consequences, such as pollution of air and water, and damage to ecosystems. We’ve already seen the staggering volume of microplastics everywhere but have yet to face the consequences (which are likely headed our way).

Additionally, nanoprinting could lead to the development of new technologies and products that could have significant impact on society. It is important to consider the potential unintended consequences of these developments.

Take the military industrial complex for example. There are valid ethical concerns surrounding the use of nanotechnology in military applications. Nanoprinting could be used to create new weapons and military technologies, which raises further ethical questions about the use of these technologies to kill people in warfare.

There is also societal controversy surrounding the use of nanotechnology in surveillance, privacy, and human rights. The development and use of nanotechnology in areas such as could have a significant impact on civil liberties and human rights, and it is important to consider these implications.

Ethics of multi-material printing

Multi-material printing technology has the potential to revolutionize the way we create and produce things. Structures are already being printed using a combination of metals, plastics, and ceramics, and in the future, it is expected to be used to create structures using a wider range of materials, such as wood and glass. This could potentially lead to the creation of more complex and customized products.

The use of 3D printing technology in construction can have a positive impact on the industry as it could reasonably reduce the time and cost of construction, increase precision, and open up new design possibilities. Using 3D printing in the aerospace industry can also lead to the reduction in weight and increase in strength of parts, leading to more fuel-efficient aircrafts.

However, because the market lacks regulation, people may be rightly concerned about moving into a 3D printed house. No reasonable person would want to move into a 3D printed home that has a risk of collapse. A 3D printed house must pass code enforcement inspections just like a traditional home, after all.

In the field of fashion, 3D printing technology is being used to create clothing, shoes and accessories. This could lead to a downward trend in sweatshop manufacturing. However, it could also automate people out of a job.

Conclusion

Congrats, you made it to the end!

As we’ve discussed, 3D printing is not only a fun hobby for DUI enthusiasts/makers, but it has incredible possibilities to significantly reform a number of very important industries. We’ve seen how 3D printing can be used to create prosthetics, dental implants, and orthotics, and other medical devices. Furthermore, 3D printing can also be used in the field of food, to create new and innovative food products, and also can be used in the field of art and architecture to create new and unique structures.

All in all, 3D printing technology has the potential to revolutionize various industries and society as a whole by providing new and innovative solutions in fields such as healthcare, electronics, manufacturing, fashion, aerospace, construction and more. As technology continues to evolve, we can expect to see more companies adopt it and create new and innovative products. It is up to the human decision makers to consider all implications of these new 3D printing processes.

It is imperative that this brave new world of 3D printing is well-regulated for the safety of everyone.

More from Chan’s World

Thank you for reading through the Ultimate Guide on 3D Printing. I hope you found it informative and insightful. If you're interested in exploring more cutting-edge technology, be sure to check out my other Ultimate Guides on the latest cutting-edge technology. Each guide is packed with expert knowledge and practical advice, so you'll be up to date on the latest trends and advancements.

Additionally, if you'd like to stay updated on my latest guides and other news, sign up for my mailing list. I'll send you regular updates and exclusive content, so you'll never miss out on what's happening in the tech world. To join, simply enter your email address below.

Join our mailing list today and keep ahead of the curve on the latest in technology!